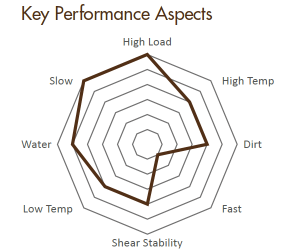

Slow speeds and heavy loads are conditions most commonly experienced in industries such as mining, construction and metal manufacturing such as steel. Consequently, vibrational activity and shock load potential is also high which means that in-service, boundary lubrication conditions tend to dominate and thus present the greatest challenge to operational productivity. Increased wear and friction can act fast to shorten component life whilst reducing lubricant effectiveness through thermal and oxidative degradation. An appropriate lubricant can aid these challenges through mechanisms that enable greater surface separation as well as protection from high and shock load conditions.

Off-shore, metalworking, mining

Gears, jacking, kilns, mills, winches, wire ropes, etc.

Load carrying ability

Resistance to vibrations and shock loads

Lubricant film formation

Download our Slow & Heavy Conditions Mat and learn more about a whole range of technologies and products (good, improved and optimal performance) you can start offering your customers today.

Download Mat

As most websites do, our website uses cookies. When you visit our website for the first time, we'll ask you to consent to our use of cookies in accordance with the terms of this policy. Click here to learn more about how we use cookies