The technology was developed by Jesco in the in the 90’s to meet customer demands for grease used in Agricultural machinery. The polyurea technology has been developed further to include both MDIs and TDIs.

The Axelurea is an ashless non-soap grease generated by the polymerization reaction of different isocyanates and amines in various base oils.

Two common isocyanates used are Methylene diphenyl diisocynate (MDI) and Toluene diisocyanate (TDI). The selection of isocyanates affects the characteristics of the finished grease.

Additives, oils and polymers are added to adjust the product towards requirements

The Axelurea thickener is characterized by its high temperature performance, inherent anti-oxidative properties and can exhibit either high shear stability or thixotropic behaviors.

Typical treat rate for a NLGI 2 grease: 10 – 14 %

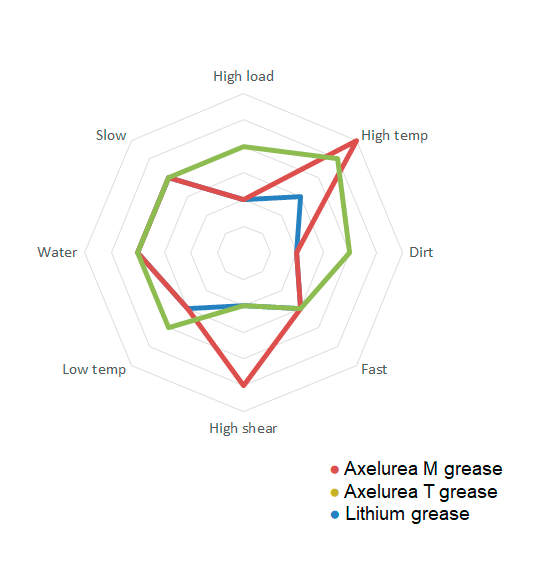

The Axelurea family currently consists of two technologies, Axelurea M (MDI) and Axelura T (TDI). Both have the advantage of being based on an ashless oxidation resistance thickener making them suitable for high temperatures. The shear stability of the MDIs enhances the performance in rolling bearings resulting in increased life. The thixotropic behavior of the TDIs gives the product excellent mobility, helps to seal the bearing from contaminants and prevents leakage.

Agricultural, forestry and Construction equipment, Multi purpose rolling bearings, Wheel bearings

Sealed for life bearings, Electrical motors, fans, etc

Automotive applications, CVJ

Steel mills, Continuous casting

Slow moving gear cases, Irrigation systams, Corn head, etc

As most websites do, our website uses cookies. When you visit our website for the first time, we'll ask you to consent to our use of cookies in accordance with the terms of this policy. Click here to learn more about how we use cookies