The patent for calcium sulfonate complex greases expired in the early in the 00s and AXEL developed our own version of this grease technology.

The Calsullence thickener consists of a complex between a gel and a calcium soap.

The gelation process takes place between calcium carbonate, acids, water and alcohol to assure that the thickener consists of calcium carbonate in form of crystalline calcite. An additional saponification step is carried out to create the complex.

The Calsullence thickener is characterized by its resistance to water and extreme pressures, shear stability and adherence to surfaces.

Typical treat rate for a NLGI 2 grease: 18 – 20 % or 30 – 32 % depending on the process chosen

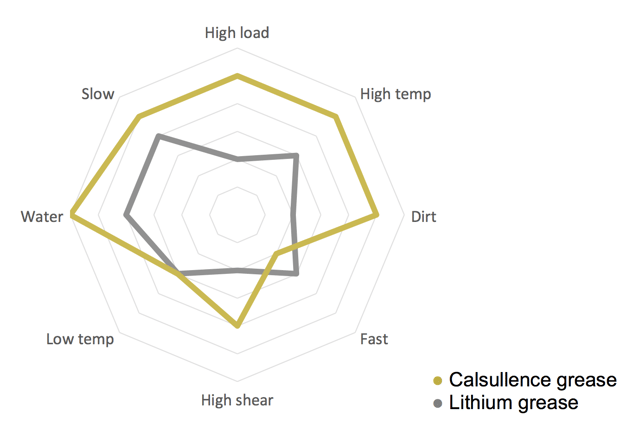

Calsullence greases have the typical advantages seen for calcium containing thickener with respect of water resisting properties and can cope with water ingress with maintained performance. In addition to the extreme load carrying properties and resistance to heavy loads, the product also adheres well to surfaces and forms a barrier towards dust and dirt. The technology is the prime choice for wet, dirty and highly loaded conditions, especially at low speed and medium to high temperatures.

Metal working industry, casters, hot mills

Mining equipment fixed and mobile plant, mills, kilns, gears, chains, etc

Extreme wet conditions in industry (paper and pulp, steel)

Food-grade applications, bottling, ovens, pellet press, etc

High load conditions in off road automotive, bushings, pins, joints, chassis components

As most websites do, our website uses cookies. When you visit our website for the first time, we'll ask you to consent to our use of cookies in accordance with the terms of this policy. Click here to learn more about how we use cookies