The ultimate grease technology for cold and wet conditions.

The technology was originally developed to lubricate fishing boats in the Caribbean Sea but has been used in many other applications such as marine, agriculture, forestry, food grade and environmentally acceptable greases.

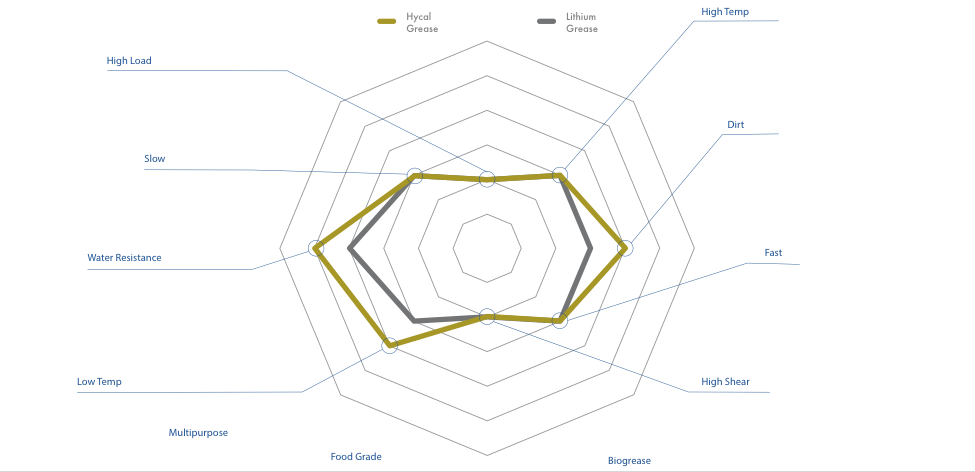

Multipurpose greases, based on lithium technology, have been the global standard for over 60 years, making up more than 70 percent of the world’s lubricating grease. The well-balanced performance of the lithium thickened greases, which makes the products suitable for a wide variety of applications, and the attractive price have been the main drivers of this dominance.

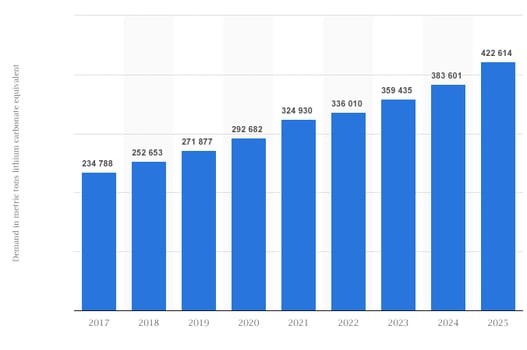

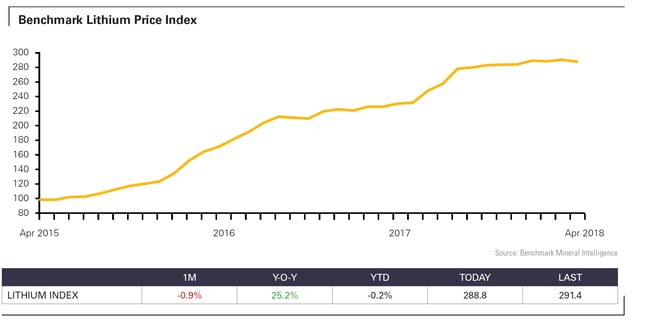

Grease producers, however, have increasingly been competing for lithium with battery and electric car manufacturers who are driving demand and higher prices across multiple industries. In some cases, where supply contracts have not been set up, grease producers also face severe shortages or are simply unable to source the raw material.

Demand continues to increase and price has surged

The Hycal thickener is made by a saponification process between calcium hydroxide and fatty acids, usually 12-hydroxy-stearic acid.

The thickener starts to melt at temperatures > 140°C, meaning that the upper temperature limit is restricted to an absolute maximum of 120°C.

The Hycal thickener is characterised by its resistance to water, low temperature rheology, shear stability and adherence to surfaces.

Typical treat rate for a NLGI 2 grease: 7 - 9 %

This technology combines a very water resistant thickener system with state-of-the-art polymers providing adhesive products which stay in place under the most extreme conditions of water wash out. In addition, the products perform extremely well at low temperatures. An extra bonus is that the thickener system is approved for food grade applications if combined with other suitable oils and components and for use in sensitive natural environments if combined with environmentally acceptable oils and additives.

Universal grease for above deck applications, such as wire ropes, in commercial shipping

Agricultural equipment and forestry processors

EAL type products (ECO-label, VGP, etc)

Recreational vehicles and vessels, boat trailers

Extreme wet conditions

Low temperature military applications, general automotive and artillery

Food-grade applications, bottling, freezers

A wide variety of moderately loaded rolling bearings

As most websites do, our website uses cookies. When you visit our website for the first time, we'll ask you to consent to our use of cookies in accordance with the terms of this policy. Click here to learn more about how we use cookies