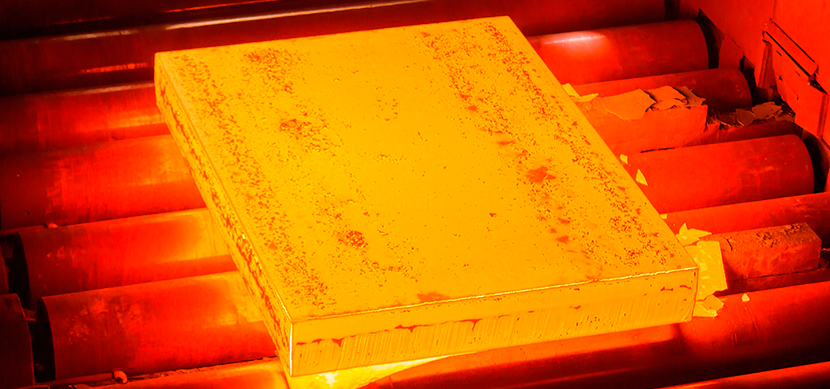

In steel manufacturing the continuous caster provides quite a challenge for lubricant formulators. The bearings supporting the hot steel material needs to handle both high and shock load conditions, vibrations, high temperatures and/or water from cooling. The demands on the grease are therefore high too, so in order to provide sufficient lubrication the proper grease technology has to be selected.

AXELs’ high performance, Calcium Sulphonate Complex based range, known as Calsullence, includes products developed specifically to meet the needs of the steel industry and have proven very successful in the field. Calsullence 1715 WR provides an additional option when a higher viscosity fluid phase is needed to support the bearings.

The calcium sulfonate complex soap makes the product suitable for heavily loaded applications operating at high temperatures and u90%wet conditions. The functional thickener provides strong protection against shock loads, good adhesion and resistance to squeeze out. The high degree of mechanical stability combined with the high viscosity ensure that the product supports the bearings under slow movement and vibrating conditions. The grease is well suited to wet conditions due to its’ high resistance to water ingress and strong corrosion protection..

Key product features include:

- Excellent EP and shock load resistance

- High fluid phase viscosity

- Excellent water resistance

Key product benefits include:

- Enhanced protection under boundary conditions

- Increased film strength under slow and heavily loaded conditions

- Protection against damage caused by water and debris