Background

Our Alassca thickener can be described as a combination of a lithium complex soap and sarcosylic calcium gel. The well-known lithium complex part forms the backbone of the thickener system and provides increased oil bleed and lubricity, and lowers total thickener content. This is important for successful use at lower temperatures. The attachment of the calcium gel to the lithium complex soap increases surface affinity and, thereby, the efficiency of these active components, providing resistance to extreme pressure, water, and corrosion. The thickener system is durable and contributes to surface separation, which means less reliance on the very high viscosity of the oil phase, in opposition to traditional aluminum complex and inorganic clay thickeners.

Performance and Applications

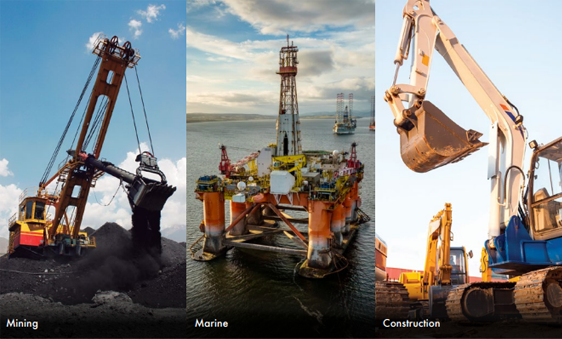

The performance capabilities of Alassca technology make it an attractive platform for applications and market segments where extreme loads and harsh elemental conditions are common. Due to its inherent structural stability, excellent load-carrying capability, and resistance to the effects of water ingress, it is particularly well suited to exposed, heavy-duty operations such as those found within the following segments:

- - Mining equipment, fixed and mobile plants, mills, kilns, gears, chains, etc

- - Pipe dope & off-shore jacking grease

- - Low-temperature mining operations

- - Wet, dirty, and highly loaded conditions in off-road and construction

- - Wires in marine and mining

Download our NEW Alassca technology brochure!

and see why it is the prime choice for wet, dirty, and highly loaded conditions, especially at low speeds and low temperatures.