Tribology International Publication compares lubrication performance under typical e-motor conditions.

Electric vehicle motors in e-drivetrains are equipped with grease-lubricated bearings operating at both low and high speeds with frequent speed changes. The grease-bearing system must secure a long lifespan and low frictional torque to improve efficiency and sustainability.

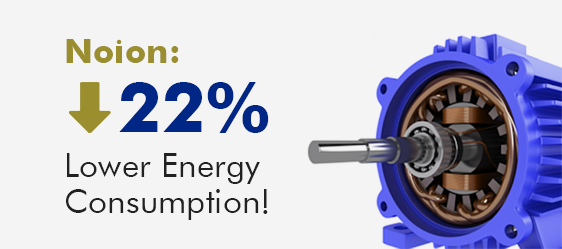

A recent publication in Tribology International compares the influence of two thickener types, namely; Lithium Complex and Polypropylene, on grease lubrication performance under conditions typical for e-motors. Evaluations of both thickeners were performed with respect to frictional torque and energy consumption in eight endurance experiments (337 hr) with results showing the Polypropylene thickener to reduce energy consumption by 22% compared to the Lithium Complex.

These results reflect those seen previously based on other tests and field trials, further demonstrating the ability of Noion greases, based on a polypropylene thickener, to reduce frictional losses within the range of 20-30% compared to a conventional soap-based grease with an identical oil composition.